ESC Environmental Services Ltd are able to meet all of your drainage requirements and, more importantly, identify the most cost-effective way to do this. If a major defect, such as a fracture or leak is found in your pipework then we are able to target and repair that specific area. The engineers have years of experience within the drainage industry and can survey, repair and replace a variety of drainage systems.

During the survey we will be able to identify the following problems:

Fractured pipes – Pressure from above, such as a heavy vehicle driving over the ground, can cause cracks and fractures in your drainage pipes. Untreated, these will leak contents into the soil, which could result in further damage to the pipe or even subsidence.

Collapsed drains – Can be caused by the drains being badly built in the first place or a variety of other reasons. If left, not only are blockages likely, but subsidence and environmental damage are possible.

Tree roots – Roots seek out moisture, so they can find their way through existing faults into the drains. Once the tree roots have entered the drain, other material will get caught in them, making blockages far more likely and frequent.

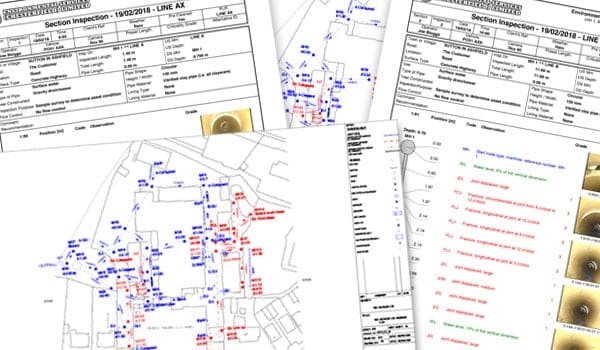

The survey hardware provides HD imagery which is viewed live on and off-site using WincanVX (Or earlier version if required) and HADDMS (For highway projects) software to save time in acting on any immediately required or major repairs. After highlighting suggested corrective works, we can advise on the most appropriate course of action from our years of experience. Full Manhole inspections can also be incorporated into the drainage survey, providing details of the overall condition of each manhole located on site.

- Full reports on drain inspections

- Over 450 independent checks

- Site Drainage Maps can be provided for future use

Instead of excavating and replacing pipes, the availability of a ‘no-dig’ lining system allows us to repair drains, sewers and culverts in a convenient and cost-effective manner. This uses a resin which is cured using water or steam. Specialism in UV light cure system means the process uses less energy for a lower carbon footprint as well as removing the risk of styrene pollution into the environment and watercourse.